7 Trends Daily

Stay updated with the latest insights and trends across various sectors.

Why Aluminum's Weight Might Just Be Its Heaviest Secret

Discover why aluminum's surprisingly light weight may hold hidden secrets that could change how we see it forever! Don't miss out!

The Surprising Benefits of Aluminum's Lightweight Nature

Aluminum's lightweight nature has long been celebrated in various industries, from aerospace to automotive manufacturing. This property not only contributes to fuel efficiency but also enhances performance by reducing the overall weight of structures and vehicles. For example, in the aerospace sector, the use of aluminum in aircraft components can lead to a significant decrease in fuel consumption, leading to lower operational costs and reduced environmental impact.

Moreover, the benefits of aluminum's lightweight nature extend beyond just industry-specific applications. Everyday products like smartphones and laptops leverage this attribute for better portability. As consumers increasingly seek convenience, the demand for lightweight yet durable materials continues to rise. This shift also aligns with sustainability goals, as lighter products typically consume less energy during transportation, ultimately contributing to a greener planet.

If you're looking for a reliable and stylish way to hold your device, check out the Top 10 Aluminum Phone Stands. These stands combine durability with a sleek design, making them perfect for any setting, whether at home or in the office. Each option is crafted to ensure stability and ease of use, providing a hands-free experience while you enjoy your favorite content.

How Aluminum's Weight Impacts Its Versatility in Industry

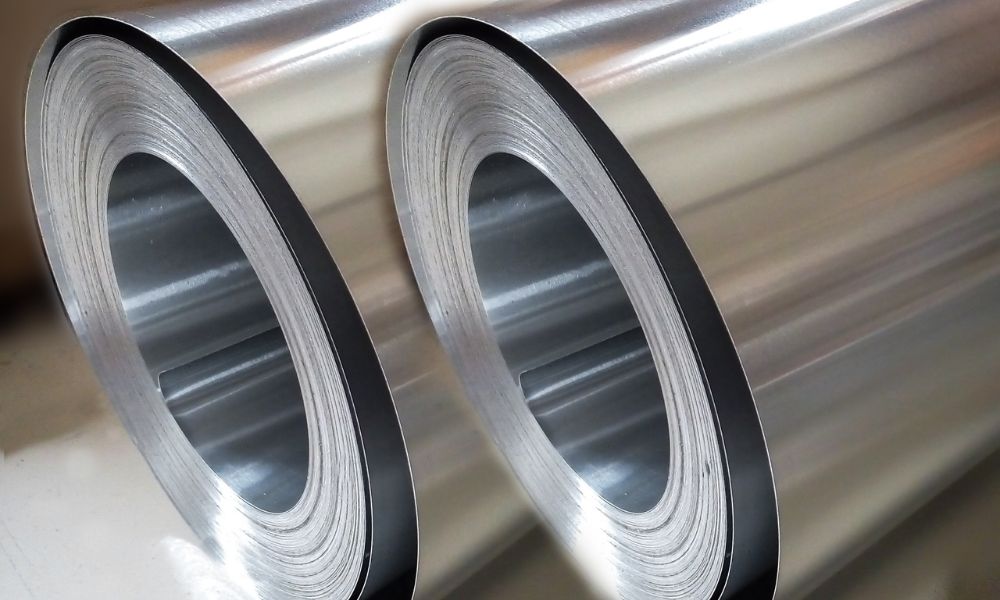

Aluminum is a marvel of modern engineering, primarily due to its lightweight nature, which significantly enhances its versatility across various industries. Weighing only one-third as much as steel, aluminum allows for easier handling and transportation, which reduces overall operational costs. This lightweight characteristic makes it an ideal choice in industries such as automotive and aerospace, where reducing weight can lead to improved fuel efficiency and performance. Moreover, the ease of fabrication and adaptability to complex designs further amplify aluminum's role in manufacturing.

In addition to its weight advantages, aluminum also exhibits excellent resistance to corrosion and a remarkable strength-to-weight ratio. These properties enable its use in diverse applications, from building materials to electronic components. The ability to create lightweight structures without compromising strength has made aluminum a preferred material in construction, where it can support larger spans and innovative designs. As industries continuously seek to enhance efficiency and sustainability, the multifaceted uses of aluminum make it a key player in shaping the future of manufacturing.

Is Lightweight Always Right? The Hidden Costs of Aluminum's Weight

The concept of lightweight materials, particularly aluminum, has long been celebrated in industries ranging from automotive to aerospace for its weight savings. However, is lightweight always the best option? While aluminum is indeed easier to handle and can contribute to improved fuel efficiency, it often comes with hidden costs such as durability issues and higher maintenance requirements. For instance, aluminum can be more susceptible to corrosion and damage under stress than other heavier materials, potentially leading to increased lifecycle costs and frequent repairs.

Moreover, when it comes to manufacturing and design, the use of aluminum might necessitate specialized fabrication techniques that can further inflate costs. The shift towards lighter designs can also compromise structural integrity, which may prove detrimental in high-stress applications. Considering the hidden costs associated with aluminum's weight, it is essential to balance lightweight benefits against factors such as strength, longevity, and overall lifecycle expenses. In this context, asking, 'Is lightweight always right?' becomes a crucial consideration for industries aiming for both performance and value.